NOTE: The product video is showing the 14" system. It is very similar but handles smaller paper than the 17" system.

PAPERFOLDER KNIFE 17" CROSS FOLD SYSTEM

The PaperFolder KNIFE 17" Cross Fold System can fold paper up to 11" x 17" into very small package inserts. This is because the first machine has 4 fold plates rather than 2. It can create up to 5 fan fold panels in the first fold, but is limited to 1 fold on the second machine, normally in half. It delivers each folded piece to the second machine as they are folded by the first.

If you need more than one fold on the second fold, see the Air Feed Cross Fold System which can make 2 folds on the second fold rather than one.

The PF Knife17 Cross Fold System can fold sheets of paper ranging from 5.5" x 8.5" to 11" x 17" in these folds. It can perform even smaller folds on some paper.

FIRST FOLDER SETUP

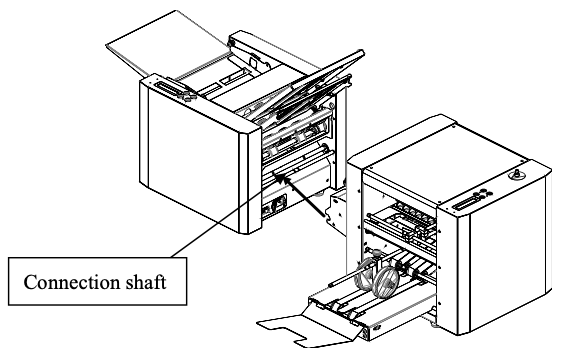

1. See the Operators Manual for setup.

2. Set the speed controls to 35%.

3. Set the fold plates as specified in the manual for the fold you want.

4. (Optional) Set the counter for the number of pieces you want to fold.

5. Run a few samples to make sure that the fold is correct.

SECOND (CROSS FOLD) SETUP

1. Remove the Knife folder, cords, output conveyor and extension from the box.

2. Remove the output wheels from inside the folder by unscrewing the nut by hand. Replace the nut.

3. Install the connecting cord between the 2 machines.

4. Attach the output conveyor and extension to the knife folder as shown in the operators manual.

5. Set the speed for the knife folder at 7 in the control panel.

6. Place the folding machine in back of the first folder as shown in the Operating Manual. There is a groove on the knife folder that fits on a bar on the back of the first folder.

7. The fold plate is set at 1/2 of the size of the width of the paper by the factory.

3. Run one or 2 samples. Make any adjustments as shown in the operators manual. Microadjustment knobs are used to fine-tune the fold resulting in crisp and accurate folds every time. The PF Knife Cross Fold Systems work best with 18# or 20# bond regular paper, not glossy or coated.

4. Start the run. The operator should not leave the machine while it is running.

5. You can stop the machine at any time by pushing the Stop button. The machine will stop when the paper input tray is empty.

ERROR REPORTING

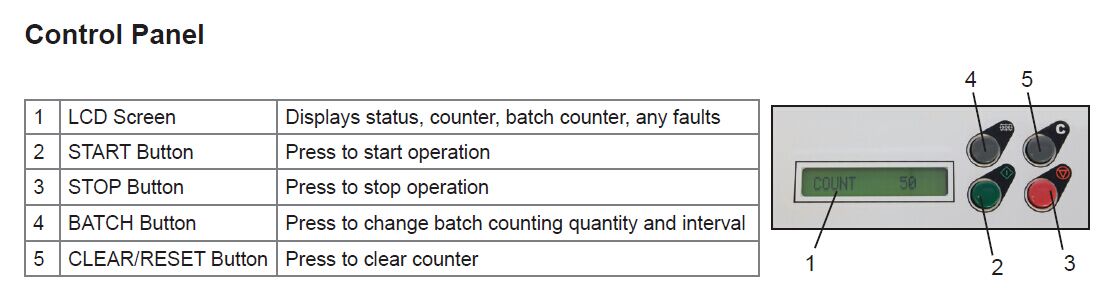

The control panel will display these messages when an error occurs:

NO PAPER

NO PAPER/ # Paper has run out. # is number of pieces folded so far.

PAPER ERROR Paper Jam or sensor needs cleaning

OVERLOAD Motor is overloaded

IF YOU NEED TO FOLD 8.5 X 14 OR SMALLER PAPER

The PF Knife 14 Cross Fold System can fold up to 14" paper into 5 panels on the length and one cross fold (2 panels) on the width.

IF YOU NEED MORE OPTIONS

The Air Feed Cross fold System can handle high volume, glossy paper, and can be configured to do many different folds.

Please call to discuss your jobs with us or if you have questions. 800-520-6008.