Folding Machine Guide

If you would like help in selecting the right machine for you, call us at 800-520-6008 for a specific recommendation. A knowledgeable, friendly person answers the phone.

There are many variations in folding machines. This short guide will help you decide upon the right machine. When you narrow it down for your jobs, go to the page that lists all folding machines by price and choose the category.

-----

1. What size paper?

In the US, these standard paper sizes are available, measured in inches.

Letter and Legal Size machines fold paper up to 8 1/2" x 14" (legal size).

Large format machines can fold larger paper, up to 11" x 17", some even larger.

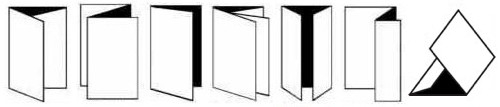

2. What kind of folds?

TWO FOLD-PLATE MACHINES (the most common)

Most folding machines have 2 fold plates and can perform 1 or 2 folds, including those seen below.

-----

-----

FOUR FOLD-PLATE MACHINES (PHARMACEUTICAL)

If you need to fold paper into very small sizes (e.g. to put instructions in small packages), you will need a specialty folding machine called a Pharmaceutical folding machine.

We have 2 sizes: The PH-14 handles letter and legal size paper; the PH-17 handles paper up to 11" x 17". They can fold paper into small sizes because pharmaceutical folders have 4 fold plates rather than 2 like most folding machines, so they can fold paper with up to 5 panels (4 folds) rather than 3 panels. 11" paper can be folded down to 2.2" and 17" down to 3.4" (1/5th the length).

Examples of the 4 and 5 panel folds are shown below.

-----

FOLDING MACHINES THAT CAN PERFORM A CROSS FOLD

A cross-fold is made when you fold paper along the length and then put it back through the machine from the side to fold it again. In our experience, only a few perform very well. If you are performing more than a few cross folds, see Cross Fold Systems below.

These are the usual cross folds.

-----

CROSS FOLD SYSTEMS

If you need to cross fold more than a few sheets at a time, you need a cross fold system. Cross fold systems consist of 2 machines placed a right angles to one another.

We have 2 systems, the Knife 14 Cross fold System for paper up to 8.5" wide x 14" long, and Knife 17 for paper up to 11" x 17". Each one can fold paper along the length in half, thirds, quarters, fifths or sixths. Then, it folds it from the side in half.

| Knife 14 Cross Fold System |

| Knife 17 Cross Fold System |

Click to open Click to open

|

|  Click to open Click to open

|

-----

3. How many sheets do you fold per month?

800 or less: Light duty machine if it is for fliers or brochures. Not recommended for letters or checks because you will have to reprint if there is a jam. They happen more often on these machines.

20,000 or less: Medium duty folding machine

150,000 or less: Heavy Duty friction-feed folding machine

150,000 and over: Air (Vacuum) Feed folding machine

-----

4. Is any of the paper glossy?

Only a few friction-feed machines (the most common) can fold glossy paper. The Dynafold 42FC and the PF-380S can unless it is very slick or thick. If it is, you will need an air (vacuum) feed.

-----

5. Lots of different folds or users?

Consider an electronic or automated setup machine. You push buttons or turn knobs to set the folds rather than set the stops on the fold plates manually.

-----

6. Fold more than one sheet at a time?

Folding machines take one sheet at a time from a stack in the feeder and fold it. There is no folding machine on the market that can automatically fold more than one sheet. Some machines have a slot that allow you to manually drop in a set of up to 5 sheets which will then be folded together.

A folder-inserter, bookletmaker or a bookletmaker combined with a collator are the only other choices. Here is a more thorough explanation.

-----

Folding machine types

All folding machines fold paper one sheet at a time (some have a manual feed where you can manually put in up to 5 sheets and the machine will fold them). Most are manual setup, friction feed machines (called friction feed because the paper is moved through the machine pinched between 2 rollers. There are also the 4 roller pharmaceutical machines discussed above). The other type is air or vacuum feed. Those are good for glossy paper and high volume.

-----

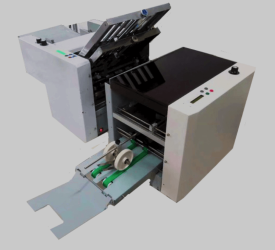

Friction Feed Folding Machines - Manual Setup

This is the FD346 large format, friction feed, manual setup folding machine. 500 sheet hopper on the left, fold plate one is upper right, fold plate 2 is barely seen lower left, and the output wheels and conveyor lower right. You set up the machine manually, then put the 1x button for a test sample. Then push the green button to go and the red one to stop. You can also set you number you want to fold.

-----

All machines have a fold chart on the body of the machine. The chart tells you where to set the stop on each of the 2 fold plates.

On manual setup machines, you set a fold by moving and tightening knobs to the position shown in the chart for that fold on the 2 fold plates. On automatic setup machines, you push some buttons and the machine sets up automatically.

Some more expensive machines have a micro adjustment which allows you to adjust the setting in very small increments.

Most machines also have adjustments for skew, such as when paper folds at an improper angle. More expensive machines also have adjustments for thickness of paper.

Next, a stack of paper (capacities range from 50 to 500 sheets) is placed in the hopper, and the machine turned on. The tray shown here can hold up to 500 sheets.

More expensive machines have more than one feed roller which feeds the paper more accurately. They can also process some coated papers.

Some machines have an output tray instead of a conveyor. It is not as useful as a conveyor. A conveyor is highly recommended for folding larger volumes of paper and is particularly useful with Z folds, which tend to get nested together.

Friction Feed Folding Machines - Automatic (Electronic) Setup

On automated setup machines, you select the size paper and the fold type from an electronic board. The machine is then automatically set up for the fold you select, a great help when you perform a number of different folds or have multiple users.

Air (Vacuum) Feed Folding Machines

Air feed machines are required for very high volume or very glossy/slippery stock (so called because they pick up the sheet of paper by air suction).

They are considerably more expensive than friction feed folders, but are more durable under high volume use. They do not slip on glossy paper like most friction machines.

There are many variations in folding machines and the right machine for a job may not be obvious. If you would like help selecting the right machine for you, please call us at 800.520.6008. We can help you wade through the details and suggest the best machines for your needs. A real person answers the phone.